The new WASP Clay kit includes a 3L tank (and upon request to info@deltawasp.com.au, a 5L tank is available). The new model now can print

middle-sized prints, something that the older iterations could not do due to the limitations on the mixture amount that could be contained.

Inside the tank, there is now a piston that pushes the material through the teflon pipes to extrude material. The tank can simply be

cleaned and refilled by removing the caps at either end of the tank. The tank is also fitted with a safety valve that is set to 8bar.

With the new design, the probability of bubbles being inside the mixture is minimised greatly. This is due to the fact that the design allows

for air to flow upwards and out of the mixture, reducing the chance of a failure mid-print due to bubbles. Furthermore, the extruder now

uses a stronger screw to feed material through, and thus can extrude more dense material, further eliminating the risk of a collapse during printing.

The screw and tank are also easily replaceable in the event of damage.

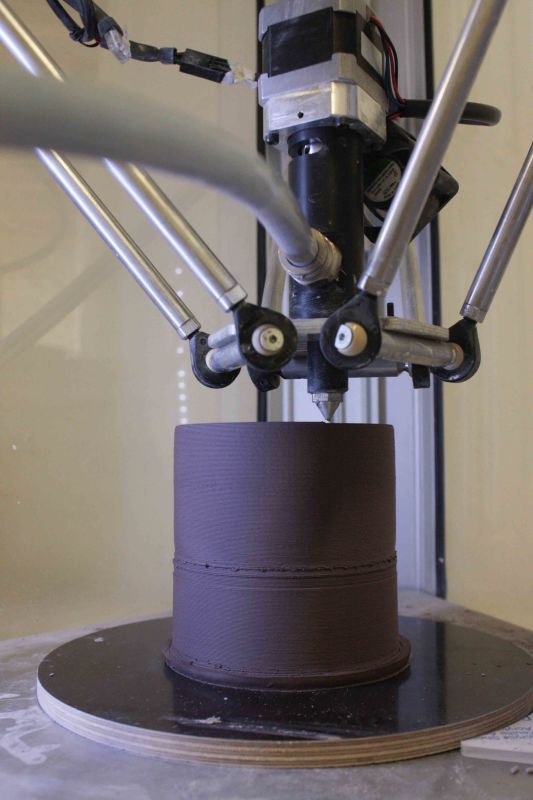

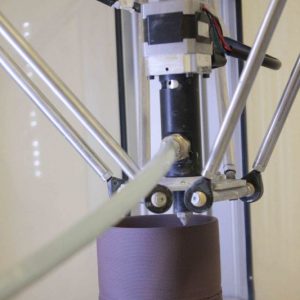

LDM WASP EXTRUDER

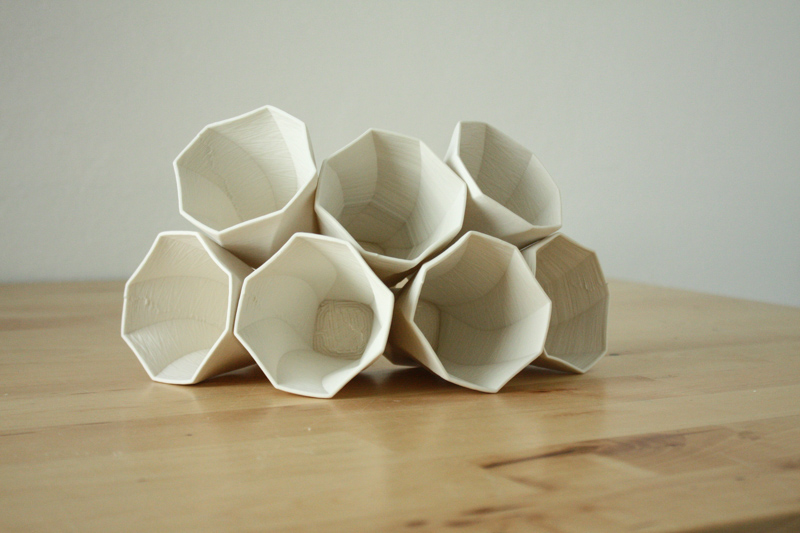

LDM (Liquid deposition modelling) is the name of the innovative WASP extruder. It can be used to print ceramic materials and can be adapted

to most 3D printers on the market.

WASP has always been primarily focused on the LDM process and the development of systems that use fluid-dense materials for printing. The

LDM extruder can be used to print materials like porcelain, clay, alumina, zirconia and advanced ceramics. In launching the new extruder

WASP aims to promote the printing of fluid-dense materials and advanced ceramics into the world.

After two years of time and experimenting all possible combinations of pressure, nozzle diameter, and materials, WASP has created an

extruder that can stop and start extruding, much like a retraction in FDM printing.

The LDM WASP extruder is a professional clay extruder that can be used to deposit dense fluid materials such as clay, and experimental materials.

With the new screw system, it is capable of regulating the output flow of the material that is being deposited, and thus it can allow a

rapid interruption of flow, and accurate retraction control.

ADAPTABILITY TO OTHER MACHINES

The WASP Clay kit was created with installation on WASP printers in mind. However, it can be adapted to most 3D printers on the market. Simply print mounts that are suitable for your machine (provided by wasp on info@deltawasp.com.au), then change your extruders’ steps per millimeter to 400.