The new 4070 ZX is provided with new motor drivers that make the printer much quieter and more precise, combined with new, more powerful stepper motors that give it greater rigidity and repeatability.

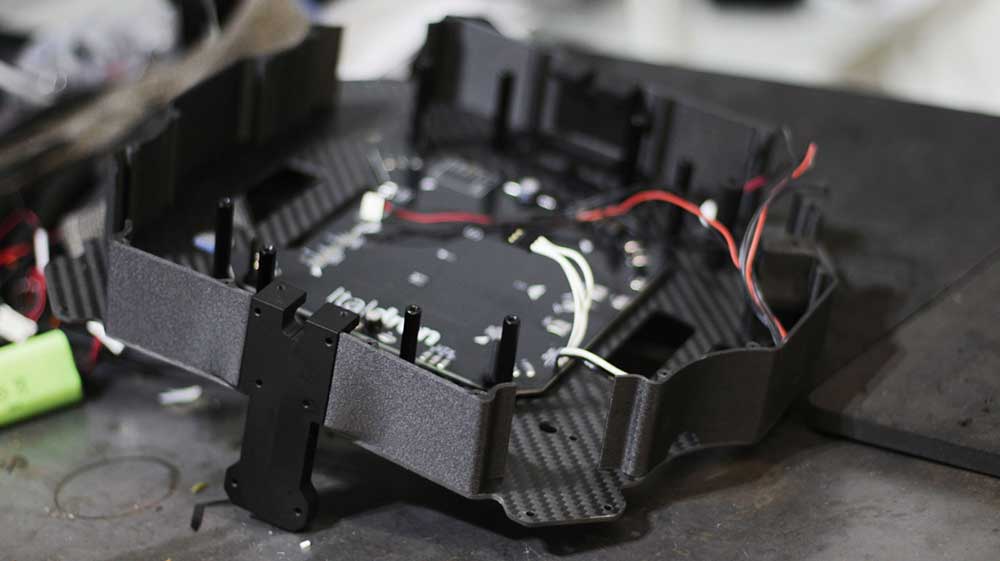

The mechanics have also been redesigned and we are proud to introduce our new carbon fibre arms, which halve the weight and increase the speed.

The new laminated safety glass door (Class 2B2) can guarantee greater thermal stability within the print build chamber.

The user experience has been further simplified with the adoption of a new 7-inch TFT colour touch display and an LED bar located at the top of the printer, which allows you to see the status remotely.

Active heated chamber

WASP 4070 ZX is manufactured in metal, with non-deformable steel core belts, featuring both thermal and acoustic insulation. The actively controlled build chamber temperature can reach up to 70 °C which allows an optimal printing of technical thermoplastics, while maintaining a relatively low temperature on the mechanics.

Remote camera control

The WASP 4070 ZX can be connected to the network and then be managed directly via mobile phone, tablet or computer. A camera has been included inside the printer to monitor printing remotely.

A team of experts for dedicated assistance

Thanks to remote intervention, WASP technicians can work on your machine’s motherboard in case of issues.

Easily interchangeable plates

The innovative vacuum retention system VAC (Vacuum Active Control), allows you to replace the printing plate in a few seconds, ensuring the total absence of micro-moves during printing even at high temperatures.

The VAC also allows you to use printing plates of different types compatible with the printing material used, ensuring excellent adhesion. Once the print is over, the VAC automatically releases the printing plate that can be curved manually.

ZENX double extruder

The WASP 4070 ZX is equipped with a double Ø1.75mm ZENX filament hot end capable of reaching 350°C.

The ZENX’s tilting system seals and automatically lifts the unused nozzle from the print surface, ensuring clean and precise printing.

Super hardened nozzles

The nozzles are easily interchangeable and made of high-speed hardened steel then subjected to electroless nickel plating to achieve our specific surface treatment to improve multi-material extrusion characteristics.

3X the extrusion force

The all-metal double gear extruders offer twice the grip and three times the force compared to common extruders.

Camera on-board

It allows for remote monitoring of the printing process including time-lapse.

Automatic leveling

Mesh plate for auto calibration.