A new approach to DLP printing

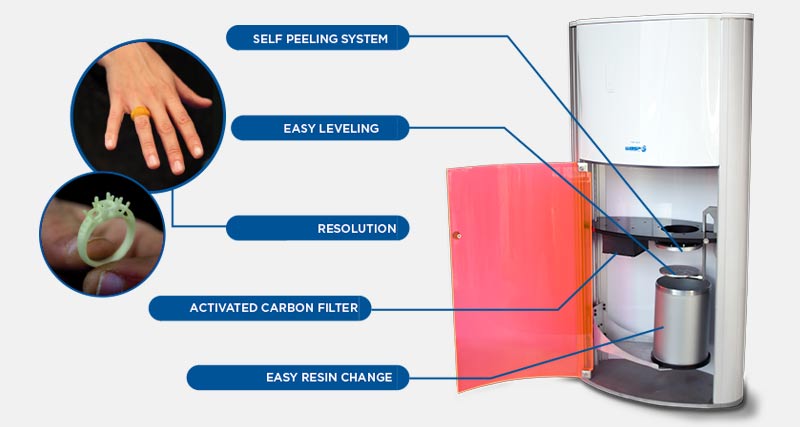

Combine the TOP DOWN PRINTER characteristics with innovative solutions such as SELF PEELING TECHNOLOGY.

The DLP printer uses a projector to emit UV light. This carefully modulated light polymerizes a photosensitive resin, solidifying it. The light generates the object in layers, and results in an accurate and precisely rendered object. This printer is best for high-precision models; such as for micromechanics and jewelry.

WASP has introduced an innovative new system for removing the printed piece from the build plate that makes this process quick and safe.

Initially, a film is immersed into the photosensitive liquid. At the beginning the film is placed over the plate that moving in coordination with the projection creates an high definition object. Due to the flexible film, each layer is easily detached from the film as the print continues, contrary to the complicated process of detachement of the other printers.

The printer includes a gas filtration system for the resins’ gases.