The 4070 Industrial X boasts an aluminium body, steel cored belts, and features thermal and acoustic insulation. The new Hot and Cold Technology allows the chamber to be heated up to 70*c, while simultaneously cooling the mechanics of the printer. This results in fast prints when using technical materials, withhout damaging the moving parts of the printer. The new Filament Driver X replaces the suspended bowden setup, doubling the grip and tripling the force when compared to a regular bowden driver. This is a direct result of two hardened steel gears within the filament driver. Also included in the Industrial X line is an auto-calibration feature.

Equiped with the WASP ZEN X extruder, printing with multiple materials up to 350*c is no challenge for the 4070 Industrial X. The new WASP Zen X extruder also allows for quick tool-changes between cartridges. The WASP FLEX extruder can simply be switched to print flexible materials down to Shore 50A within minutes.

The Industrial X Series can be connected to WiFi in order to monitor and send gcode through remotely from your smart device or PC. There is a camera installed inside to monitor your prints.

Technical Specifications

Build volume: Ø 400 x h 700 mm

Heated chamber: heated up to 70°C

Minimum layer height: 100 micron

Print speed max(*): 200 mm/s

Travel speed max(*): 300 mm/s

Acceleration(*): 6.000 mm/s2

Bed temperature max: 120 C°

Nozzle diameter standard: WASP ZEN X Extruder with MT cartridge, nozzle 0,7 mm

* All data relative to speed make reference to a Delta WASP 4070 Industrial X with WASP ZEN X Extruder 0.4 mm.

MATERIALS

Suitable filaments

Ø1.75 with “WASP ZEN X Extruder”

Ø2.85 with “WASP FLEX Extruder”

ASA

ABS

HIGH-IMPACT PS

PETG

POLYCARBONATE

PC+ABS

PPS

PMMA

PVA

PA

PA carbon

PLA

TPU *only with FLEX Extruder

TPE *only with FLEX Extruder

POLYPROPYLENE *only with FLEX Extruder

CONFIGURABLE TOOLS

WASP ZEN X Extruder: dual extruder for single material, multicolor or multimaterial prints, with end filament sensor.

Nozzle diameter: 0.4 mm, 0.7 mm, 1.2 mm (filament diameter 1.75 mm)

WASP FLEX Extruder: direct drive extruder for flexible materials down to shore 50A.

Nozzle diameter: 0.4 mm, 0.7mm (filament diameter 3 mm)

SOFTWARE

Operative systems: Windows, Mac, Linux

Slicing software: compatible with all slicing software (Cura – SLic3r – Simplify3D®)

File type: .stl, .obj, .gcode

INTERFACE

Pendrive USB

Wifi network

Display TFT touch

PHYSICAL DIMENSIONS

Dimensions: 85 cm x 77 cm x 195 cm

Machine weight: 90 kg

Dimensions for shipping the machine with wooden packaging: 100 cm x 100 cm x 230 cm, weight 250 kg

SUPPLY

Input: 220/240 V 50/60 Hz (110 V available)

Absorbed power:

WASP ZEN X Extruder: 120 W max

Hot bed: max 1300 W

Room heater: max 1500 W

TEMPERATURE

Use: 20-30 C°;

Warehouse: 0-30 C°;

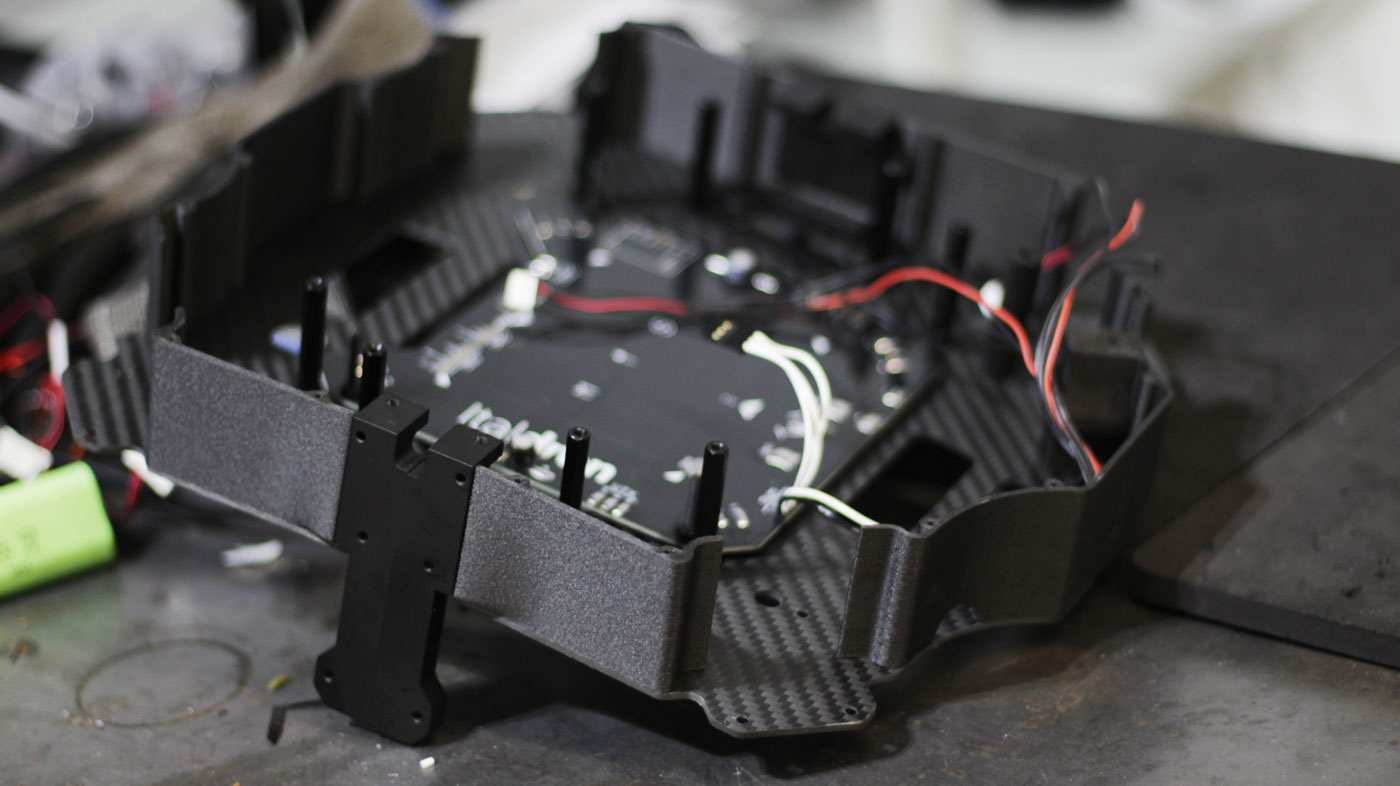

MECHANICS

Frame and cover: aluminum, steel, polycarbonate, PU. All metal body for a stiff and vibration free precise machine

Bed: machined aluminum

Movements: nylon wheels on anodized aluminum sliders PU steel core belts, resistant to high temperature

Insulation: polymer foam for thermo-acoustic insulation

Motors: Stepper

TECHNICAL INNOVATION

Continuous Print: when the used extruder runs out of filament, the print continues with the other extruder (if correctly loaded)

Bed safety sensor: automatic system that avoids the collision of the extruder on the plate. automatic security system.

Gcode analyzer: gcode error checking system.

Auto check: automatic error recognition routine.

Mesh auto calibration: mesh plate calibration.

Hot and Cold tecnology: heated chamber and cooled mechanics.

WIFI: machine connected to the network for monitoring and control.

New GUI: new touch interface with bigger TFT display.

Camera on-board: for monitoring and timelapse.

Remote support: WASP technicians can work remotely on your machine in case of issues.

EXTRA

Hot and Cold tecnology: heated chamber and cooling of the mechanics

WIFI: machine connected to the network for monitoring and control

New GUI: new touch interface with bigger TFT display

Camera on-board: for monitoring and timelapse

Remote intervention: WASP technicians can work from remote on your machine in case of issues

HOT & COLD TECHNOLOGY (cc)

An efficient way of heating by two internal heat sources, makes possible to ensure work temperatures up to 80 °C, without burdening the mechanical parts of the machine. Read more >>

RESURRECTION SYSTEM (cc)

A system which allow users to save their print job and resume it in the case of power failure. Read more >>

FREE ZETA SYSTEM (cc)

It allows to print a file starting from a precise height of the model to be printed, height previously selected. Read more >>

INCLUDED MATERIAL

1kg of PLA in spool

Packaging for national/international shipping in wooden box (100 cm x 100 cm x 230 cm, peso 250 kg).